Milk Mixing Vat Manuals

Listed below are common practices that may or may not be applicable to the products described in this manual.

Look for the Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to personal safety and extra precaution must be taken. When you see this symbol, be alert and carefully read the message that follows it. Hazard control, and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance, and storage of equipment.

Be Aware of Signal Words

A signal word designates a degree or level of hazard seriousness. They are:

DANGER:

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

WARNING:

Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

Listed below are common practices that may or may not be applicable to the products described in this manual.

Safety at All Times

Careful operation is your best assurance against an accident. All operators, no matter how much experience they may have, should carefully read this manual and other related manuals before operating this power machine and this implement.

- Thoroughly read and understand the “Safety Label” section. Read all instructions noted on them.

- Do not operate the equipment while under the influence of drugs or alcohol as they impair the ability to safely and properly operate the equipment.

- The operator should be familiar with all functions of the power machine and attached implement, and be able to handle emergencies quickly.

- Keep all bystanders away from equipment and work area.

- Operate power machine and controls from the driver’s seat only.

- Never dismount from a moving power machine or leave power machine unattended with engine running.

- Do not allow anyone to stand between implements and power machine while attempting to connect or disconnect them.

- Keep hand, feet and clothing away from power-driven parts.

- While transporting and operating equipment, watch out for objects overhead and along side such as fences, trees, buildings, wires, etc.

- Do not turn power machine so tight as to cause hitched implement to contact the power machine’s rear wheel.

- Store implement in a safe and secure area where children do not plate. When needed, secure implement against falling with support blocks and/or shipping locks.

Safety Precautions for Children

Tragedy can occur if the operator is not alert to the presence of children. Children are generally attracted to implements and their work.

- Never assume children will remain where you last saw them.

- Keep children out of the work area and under the watchful eye of a responsible adult.

- Be alert and shut the implement and power machine down if children enter the work area.

- Never carry children on the power machine or implement. There is not a safe place for them to ride. They may fall off and be run over or interfere with the control of the power machine.

- Never allow children to operate the power machine, even under adult supervision.

Power Machine Shutdown & Storage

- If engaged, disengage power take-off.

- Park on solid, level ground and lower implements to ground or onto support blocks.

- Put power machine in part or set park brake

- Turn off engine and remove ignition key to prevent unauthorized starting.

- Relieve all hydraulic pressure to auxiliary hydraulic lines.

- Wait for all components to stop before leaving the operator’s seat.

- Use steps, grab-handles and anti-slip surfaces when stepping on and off the power machine.

Use a Safety Chain

- A safety chain will help control drawn machinery should it separate from the power machine or tow vehicle.

- Use a chain with the strength rating equal to or greater than the gross weight of the towed implement

- Attach the chain to the power machine’s or tow vehicle’s draw bar support or other specified anchor location. Allow only enough slack in the chain to permit turning.

- Always hutch the implement to the machine towing it. Do not use the safety chain to tow the implement.

Tire Safety

- Tire changing can be dangerous and must be performed by trained personnel using the correct tools and equipment.

- Always properly match the wheel size to the properly sized tire.

- Always maintain correct tire pressure. Do not inflate tires above the recommended pressures shown in the Operator’s Manual or printed on the tires themselves.

- When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available.

- Securely support the implement when changing a wheel.

- When removing and installing wheels, use wheel handling equipment adequate for the weight involved.

- Make sure wheel bolts have been tightened to the specified torque.

Practice Safe Maintenance

- Understand procedure before doing work. Refer to the Operator’s Manual for additional information.

- Work on a level surface in a clean, dry area that is well-lit.

- Lower implement to the ground and follow all shutdown procedures before leaving the operator’s seat to perform maintenance

- Do not work under any hydraulically supported equipment. It can settle, suddenly lead down, or be lowered accidentally. If it is necessary to work under the equipment, securely support it with stands or suitable blocking beforehand.

- Use properly grounded electrical outlets and tools.

- Use correct tools and equipment for the job that are in good condition.

- Allow equipment to cool before working on it.

- Disconnect battery ground cable (-) before servicing or adjusting electrical systems or before welding on implement.

- Inspect all parts. Make certain parts are in good condition & installed properly.

- Replace parts on this implement with genuine Hatfield parts only. Do not alter this implement in a way which will adversely affect its performance.

- Do not grease or oil implement while it is in operation.

- Remove any buildup of grease, oil, and/or debris.

- Always make sure any material and waste products from the repair and maintenance of the implement are properly collected and disposed.

- Do not weld or torch galvanized metal as it will release toxic fumes.

Prepare for Emergencies

- Be prepared if a fire starts

- Keep a first aid kit and fire extinguisher handy.

- Keep emergency number for doctor, ambulance, and fire department near the phone.

Use Safety Lights and Devices

- A slow-moving power machine can create a hazard when driven on public roads. They are difficult to see, especially at night. Use the Slow-Moving Vehicle (SMV) Sign when on public roads.

- Flashing warning lights and turn signals are recommended whenever driving on public roads.

Wear Personal Protective Equipment

- Wear protective clothing and equipment appropriate for the job such as safety shoes, safety glasses, hard hat, dust mask, and ear plugs.

- Clothing should fit snug without fringes and pull strings to avoid entanglement with moving parts.

- Prolonged exposure to loud noise can cause hearing impairment or hearing loss. Wear suitable hearing protection such as earmuffs or earplugs.

- Operating a machine safely requires the operator’s full attention. Avoid wearing headphones while operating

Use Seat Belt and ROPS

- Use of a CAB or roll-over-protective-structures (ROPS) and seat belt is recommended in almost all power machines.

- If ROPS is in the locked-up position, fasten seat belt snugly and securely to help protect against serious injury or death from falling and machine overturn.

Avoid High Pressure Fluids

- Escaping fluid under pressure will penetrate the skin or eyes causing serious injury.

- Relieve all residual pressure before disconnecting hydraulic lines or performing work on the hydraulic system.

- Make sure all hydraulic fluid connections are properly tightened/torqued and all hydraulic hoses and lines are in good condition before applying pressure to the system.

- Use a piece of paper or cardboards, NOT BODY PARTS, to check for suspected leaks.

- Wear protective gloves and safety glasses or goggles when working with hydraulic systems.

- DO NOT DELAY. If an accident occurs, seek immediate

Keep Riders Off Machinery

- Never carry riders on the tractor or implement.

- Riders obstruct operator’s view and interfere with the control of the power machine.

- Riders can be struck by objects or thrown from equipment.

- Never use the power machine to lift or transport riders.

Avoid Crystalline Silica (quartz) Dust

Because crystalline silica is a basic component of sand and granite, many activities at construction sites produce dust containing crystalline silica. Trenching, sawing and boring of material containing crystalline silica can produce dust containing crystalline silica particles. This dust can cause serious injury to the lungs (silicosis).

There are guidelines which should be followed if crystalline silica (quartz) is present in the dust.

- Be aware of and follow OSHA (or other local, State, or Federal) guidelines for exposure to airborne crystalline silica.

- Know the work operations where exposure to crystalline silica may occur.

- Participate in air monitoring or training programs offered by the employer.

- Be aware of and use optional equipment controls such as water sprays, local exhaust ventilation, and enclosed cabs with positive pressure air conditioning if the machine has such equipment. Otherwise, respirators shall be worn.

- Where respirators are required, wear a respirator approved for protection against crystalline silica containing dust. Do not alter respirator in any way. Workers who use tight-fitting respirators can not have beards/mustaches which interfere with the respirator seal to the face.

- If possible, change into disposable or washable work clothes at the work side; shower and change into clean clothing before leaving the work site.

- Do not eat, drink, use tobacco products, or apply cosmetics in areas where there is dust containing crystalline silica.

Handle Chemicals Properly

- Protective clothing should be worn.

- Handle all chemicals with care.

- Follow instructions on container label.

- Agricultural chemicals can be dangerous. Improper use can seriously injure persons, animals, plants, soil, and property.

- Inhaling smoke from any type of chemical fire can be a health hazard.

- Store or dispose of unused chemicals as specified by the chemical manufacturer.

Dig Safe — Avoid Underground Utilities

- USA: Call 811. CAN: digsafecanada.ca Always contact your local utility companies (electrical, telephone, gas, water, sewer, and others) before digging so that they may mark the location of any underground services in the area.

- Be sure to ask how close you can work to the marks they positioned.

Transport Safely

- Comply with federal, state and local laws.

- Use towing vehicle and trailer of adequate size and capacity. Secure equipment towed on a trailer with tie downs and chains

- Sudden braking can cause a towed trailer to swerve unexpectedly. Reduce speed if towed trailer is not equipped with brakes.

- Avoid contact with any overhead utility lines or electrically charged conductors.

- Always drive with load on end of loader arms low to the ground.

- Always drive straight up and down steep inclines with heavy end of skid steer on the “uphill” side

- Maximum transport speed for an attached equipment is 20 mpg (32km/h). DO NOT EXCEED

- As a guideline, use the following maximum speed weight ratios for attached equipment: 20 mph (32 km/h) when weight of attached equipment is less than or equal to the weight of the tow vehicle. 10 mph (16 km/h) when weight of attached equipment exceeds the weight of the tow vehicle but not more than double the weight.

- IMPORTANT: Do not tow a load that is more than double the weight of the vehicle towing the load.

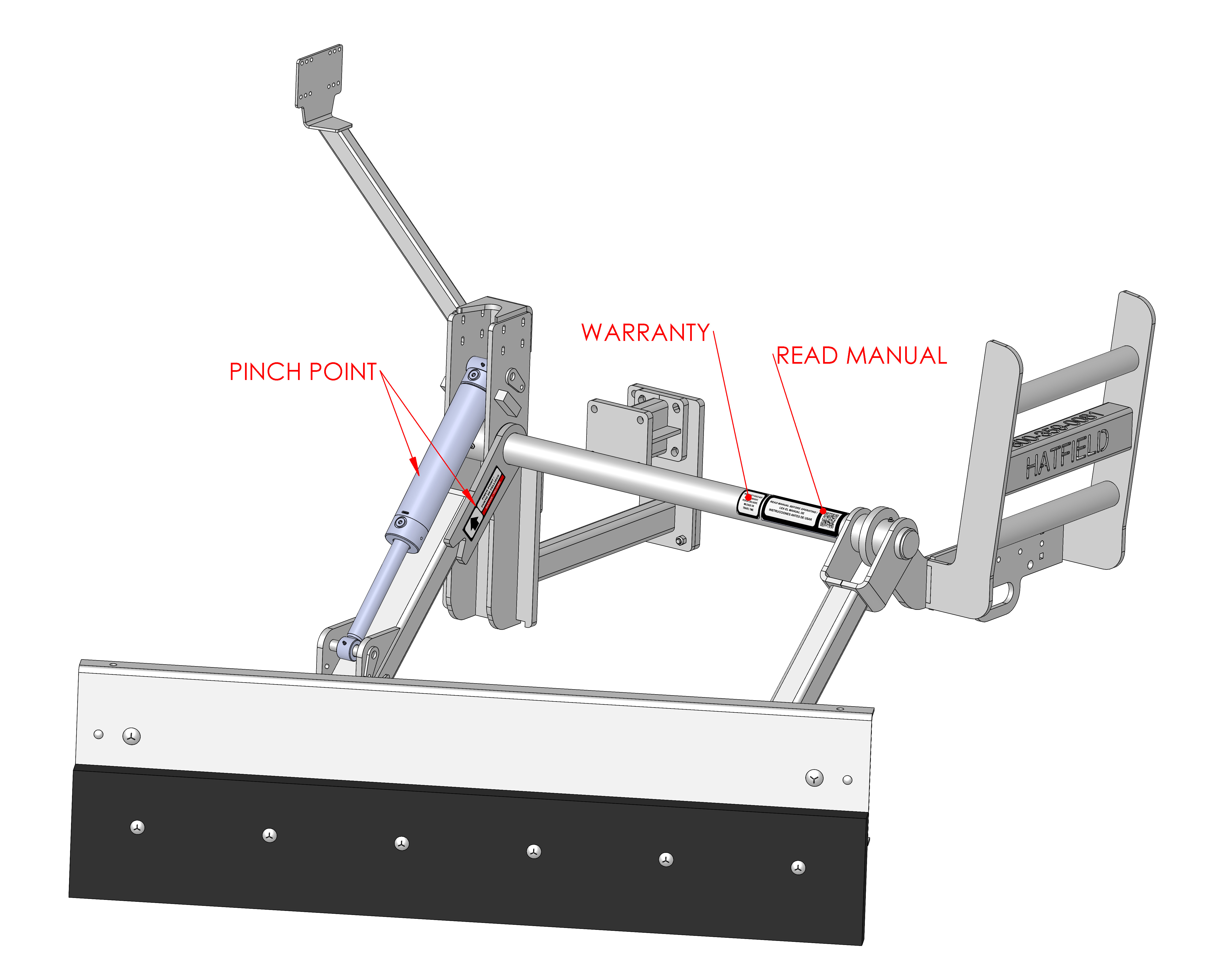

Safety Labels

Your Push Blade comes equipped with all safety labels in place. They were designed to help you safely operate your equipment. Read and follow their directions.

- Keep all safety labels clean and legible.

- Refer to this section for proper label placement. Replace all damaged or missing labels. Order new labels from www.hatfieldmfg.com.

- Some new equipment installed during repair requires safety labels to be affixed to the replaced component as specified herein. When ordering new components make sure the correct safety labels are included in the request.

- Refer to this section for proper label placement. To install new labels: Clean Surface area where label is to be placed. Spray soapy water onto the cleaned area. Peel backing from label and press label firmly onto the surface. Squeeze out air bubbles with edge of a credit card or with a similar type of straight edge.

Labels for your Push-up Blade are sold in packages containing all the safety labels you need.

Specifications

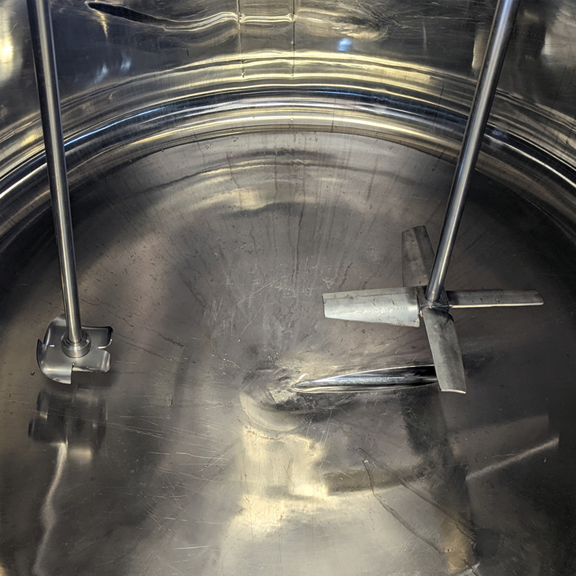

- Model: Milk Mixing Vat

- Agitators:

- Mixer (high speed): 1.5 hp/56C Frame (Direct Drive) 1750 rpm Impeller: 4 in. Mixed Flow (Stainless)

- Agitator (low speed): 1.5 hp/56C Frame (500 Gallon only) F02235 (Gear Drive) 350 rpm Impeller: 15 in. HYFLO 218 Note: when ordering parts for agitators, you must have the serial no. and shaft size

- Discharge Pump: Thomsen No. 4, externally sealed.

- Power Needs: 480V – 3 phase – 4 wire (must also have separate ground wire) Scale (if equipped):

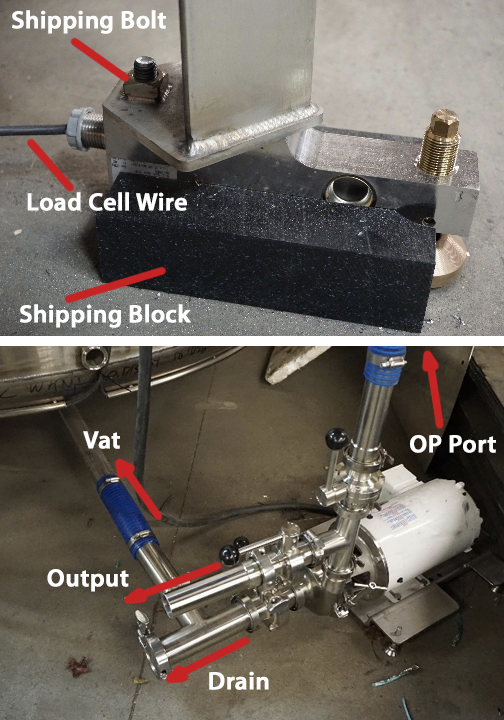

- Load Cells: Rice Lake RLSB250T-2.5k (x3)

- Indicator: Avery Weigh-tronix Model ZM301

Operating the Milk Mixing Vat

WARNING

To avoid serious injury or death:

Read all instructions before attempting to operate this equipment. Obey all warning labels on machine.

- Installation of power and plumbing must be done by qualified personnel and in accordance with all codes, regulations and laws that apply to your facility.

- Never reach into, climb into or put any implement into the machine without first shutting off the power to the machine.

- This machine is designed for mixing and dispensing milk (formula) for animals and should not be used for other materials, nor should it be used for mixing anything for human consumption.

- HIGH VOLTAGE! Follow power lock out procedures prior to working on the electrical components.

- Be on the lookout for damaged or loose wiring and replace immediately!

Installation

- Your Milk Mixing Vat is shipped nearly fully assembled. Here are the steps to install it.

- IMPORTANT! If scales are equipped on vat, it must be directly grounded using the included 6-foot grounding rod kit. Drilling through the floor, driving the rod into the earth and attaching the clamp and wire is more easily done before placing the tank especially if the tank is going to be against a wall or in a corner. We recommend installing this close to where the most out of the way leg of the tank will sit.

- CAUTION! During shipping, installation and use; care must be taken to not damage the wires coming out of the back of the load cells on the feet.

- Remove any packing materials and all components that were shipped inside the tank.

- Remove plastic shipping feet by unbolting the rear bolt on each foot from underneath, these bolts must be replaced with the stainless steel ones included in the components.

- Set the Vat in its final location on a surface that will handle its loaded weight.

- Level the vat using the built-in leveling feet.

- Bring the discharge pump down to the floor, level it and connect it to the line coming out of the bottom of the tank using the short flex hose and clamps. IMPORTANT! – Flex hose should be as straight as possible and not put any upward or downward pressure on the fitting, if it does it will affect the scale accuracy.

- Attach the 58” flex hose to the 90-degree CIP port at the top of the tank with clamps.

- The final output connection at the discharge pump is to connect your distribution hose and manifold or other device for filling bottles.

- Wire the discharge pump into the control box (if equipped, see Appendices for a diagram)

- If unit is not equipped with a control box, then discharge pump, and agitator(s) will need to be wired and switched by a qualified person.

- If unit is equipped with a control box then 480V 3-phase need only be wired to the control box by a qualified person.

- If scale is equipped, the load cells are in the feet. Unit must be directly grounded to the included 6-foot grounding rod. Attach the wire to the leg ABOVE one of the feet with the provided clip.

- There are three vertical inlet pipes on the top of the tank for bringing in liquid (Hot water, cold water, etc.). IMPORTANT! – If vat is equipped with scales, inlet pipes must be installed with an air gap (no contact) or the scale accuracy is affected.

- Vats are intended to be drained at the unused side of the “T” opposite the discharge pump by unfastening the clamp and removing the cap. If other drain valving or piping is desired it should be connected there.

- IMPORTANT! All electrical connections must be waterproof to maintain the washdown grade status of the electronics! This is most easily accomplished by passing them through the bottom port on the control box.

Operating Instructions

Scale Function

- If your vat is equipped with a scale, refer to the included owner’s manual and understand its function. It is especially important that you tare (zero) the scale before adding any material to the tank.

Filling the Tank

- Always add liquid first. Do not start the mixer or agitator until after you have added enough liquid to keep the impeller blades completely covered while running. Spinning the impellers without enough liquid will damage the shafts and motors and void the warranty.

Mixing

- Once you have enough liquid, start the mixer (and the agitator on the 500 gallon). You can now add the dry ingredients at any time while the mixer is running. Once all ingredients have been added, let the mixer run until the solution is thoroughly blended.

Dispensing

- When you are ready to dispense, make sure that the ball valve from the bottom of the tank to the discharge pump is open, the valve from the pump to the dispenser is open, and that the drain the CIP ports are closed. If your mixture has undissolved solids (most do), it is important that you leave the mixing motor running (or just the agitator on the 500-gallon model) while dispensing to maintain homogeneity. Make sure you shut off whichever impeller is running when the milk gets too low to keep it covered.

- TIP: If a scale is equipped you can note the weight when you had enough water to start the mixer, then shut off whichever impeller you are using when you empty the tank down to the same weight, this saves you from having to check the liquid level by opening the tank.

Cleaning

- Our mixing vats have CIP or Clean in Place technology and are washdown grade. The outside of the machine should be cleaned at the same time as the inside.

- To clean the vat first empty it by opening the drain side of the “T” and rinse it with the drain still open.

- Close the drain and fill the vat partially with hot water and the detergent of your choice.

- Leave the valve from the tank to the discharge pump open, close the dispensing valve and open the valve that goes to the top of the tank (CIP valve).

- Turn on the discharge pump and the cleaning solution will be recirculated back through a spray head in the top of the tank. This will clean out the tank and the discharge line. Turn the mixer on for a short time then shut it off and do the same with the agitator (if installed). Once the machine is clean open the dispensing valve and close the CIP valve to run the solution through the dispensing manifold.

- TIP: As long as the agitators are turned OFF you can place the manifold inside the vat and run the detergent through it continuously. The CIP valve can be opened back up to clean the outside of the manifold too!

- Shut the discharge pump off, drain and rinse the vat and repeat the procedure with clean water to flush the detergent out of the lines.

- Dry off the outside of the machine after everything is drained.

Main Office & Manufacturing

1823 Shoestring Road | Gooding, Idaho 83330 | Toll Free: 800.359.8171 | 208.934.5182 | Fax: 208.934.8892

Sales | Parts | Manuals | Financing | Our Company | Contact Us

2025 Hatfield Manufacturing, Inc.